Pergi ke luar talian dengan aplikasi Player FM !

E6S-210 Process Pulse Part 2 - (SPC) 8 Rules

Manage episode 217262610 series 1169428

Like / Dislike **We'd Appreciate Your Opinion**

Email me: aaron@e6s-methods.com

Leave a Review! http://bit.ly/E6S-iTunes;

Donations: http://bit.ly/E6S-Donate

Intro: Welcome to the E6S-Methods podcast with Jacob and Aaron, your weekly dose of tips and tricks to achieve excellent performance in your business and career. Join us as we explore deeper into the practical worlds of Lean, Six Sigma, Project Management and Design Thinking. In this episode number 210, we continue our "Process Pulse" series with part 2 - the 8 rules of statistical process control. If you're just tuning in for the first time, find all our back episodes at our podcast table of contents at e6s-methods.com. If you like this episode, be sure to click the "like" link in the show notes. It's easy. Just tap our logo, click and you're done. Tap-click-done! Here we go. http://bit.ly/E6S-210 Leave a Review! http://bit.ly/E6S-iTunes

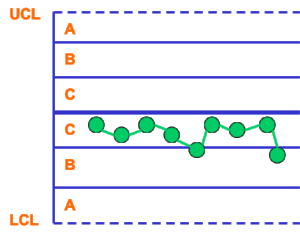

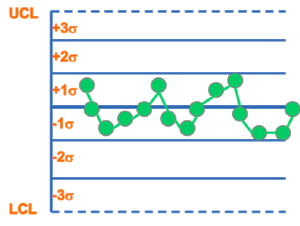

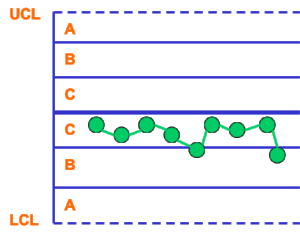

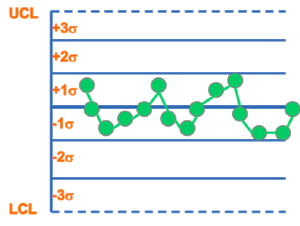

I Western Electric Rules - 8 Rules

a. Identifies low probability events. (Roughly a 3 in 1000 probability event)

i. varies by which Rule

ii. Seems to vary by geography and culture (some want to flag 1 in 100 probability)

iii. Events are neither good, nor bad, just different. The engineer or operator decides if events are favorable or not.

b. Rule 1: one point more than 3 sigma from center line

i. May signify a large abrupt change in the process; requires immediate action

c. Rule 2: nine points in a row on one side of the center line

i. May signify a shift in the process mean or bias in setpoint

d. Rule 3: six points in a row steadily increasing or decreasing

i. May signify a steady trend, drift due to wear, environment, depletion, or increasing contamination

e. Rule 4: fourteen points in a row alternating up and down

i. May signify two sources, bias, or ‘fudged’ data, over adjustment, shift-to-shift / machine-to-machine / person-to-person variation

f. Rule 5: two out of three points (same side) more than 2 sigma from center line

i. May signify an abrupt process shift, high variation without exceeding the three sigma limit.

g. Rule 6: four out of five points (same side) more than 1 sigma from center line

i. May signify a process shift, a step change (operator, procedure, materials)

h. Rule 7: fifteen points in a row within 1 sigma of center line

i. May signify reduced process variation (old or incorrect limits). For Xbar, can signify when variation within subgroup large compared to between subgroups

i. Rule 8: eight points in a row more than 1 sigma from center line

i. May signify a mixture of factors, erratic behavior, over control, two different processes on the same chart

II Typical errors to doing SPC

a. Not doing it

b. Not doing it in real time

i. Doing it a month after the fact for a customer report but not using it to refine your process

c. Leaving it up to the engineer or intern

i. Doing it right means proper training to shop floor and delegating the authority to stop a process if needed

d. Using lack of software or technology as an excuse

i. The most effective way is to be done by hand by the operator making the parts. Shewhart invented it this way.

e. Choosing the wrong type of chart

f. Not updating control limits after a significant process change

III Recap

a. SPC History- invented by Walter A. Shewhart working for Bell Labs in the 1920s

b. Monitors the health (pulse) of the process, and detects unanticipated change. (ekg reading?)

c. Different types of SPC charts - Most Basic I-MR, XbarR, P, U

d. Western Electric Rules - 8 Rules - Identifies low probability events. (neither good, nor bad, just different)

e. Typical errors to doing SPC, 1) Not doing it, 2) Not doing it in real time

Outro: Thanks for listening to episode 210 of the E6S-Methods podcast. Don't forget to click "like" or "dislike" for this episode in the show notes. Tap-click-done! If you have a question, comment or advice, leave a note in the comments section or contact us directly. Feel free to email me "Aaron," aaron@e6s-methods.com, or on our website, we reply to all messages. If you heard something you like, then share us with a friend or leave a review. Didn't like what you heard? Join our LinkedIn Group, and tell us why. Don't forget you can find notes and graphics for all shows and more at www.E6S-Methods.com. "Journey Through Success. If you're not climbing up, you're falling down." Leave a Review! http://bit.ly/E6S-iTunes

81 episod

E6S-210 Process Pulse Part 2 - (SPC) 8 Rules

E6S-Methods Lean Six Sigma Performance Podcast with Aaron Spearin & Jacob Kurian

Manage episode 217262610 series 1169428

Like / Dislike **We'd Appreciate Your Opinion**

Email me: aaron@e6s-methods.com

Leave a Review! http://bit.ly/E6S-iTunes;

Donations: http://bit.ly/E6S-Donate

Intro: Welcome to the E6S-Methods podcast with Jacob and Aaron, your weekly dose of tips and tricks to achieve excellent performance in your business and career. Join us as we explore deeper into the practical worlds of Lean, Six Sigma, Project Management and Design Thinking. In this episode number 210, we continue our "Process Pulse" series with part 2 - the 8 rules of statistical process control. If you're just tuning in for the first time, find all our back episodes at our podcast table of contents at e6s-methods.com. If you like this episode, be sure to click the "like" link in the show notes. It's easy. Just tap our logo, click and you're done. Tap-click-done! Here we go. http://bit.ly/E6S-210 Leave a Review! http://bit.ly/E6S-iTunes

I Western Electric Rules - 8 Rules

a. Identifies low probability events. (Roughly a 3 in 1000 probability event)

i. varies by which Rule

ii. Seems to vary by geography and culture (some want to flag 1 in 100 probability)

iii. Events are neither good, nor bad, just different. The engineer or operator decides if events are favorable or not.

b. Rule 1: one point more than 3 sigma from center line

i. May signify a large abrupt change in the process; requires immediate action

c. Rule 2: nine points in a row on one side of the center line

i. May signify a shift in the process mean or bias in setpoint

d. Rule 3: six points in a row steadily increasing or decreasing

i. May signify a steady trend, drift due to wear, environment, depletion, or increasing contamination

e. Rule 4: fourteen points in a row alternating up and down

i. May signify two sources, bias, or ‘fudged’ data, over adjustment, shift-to-shift / machine-to-machine / person-to-person variation

f. Rule 5: two out of three points (same side) more than 2 sigma from center line

i. May signify an abrupt process shift, high variation without exceeding the three sigma limit.

g. Rule 6: four out of five points (same side) more than 1 sigma from center line

i. May signify a process shift, a step change (operator, procedure, materials)

h. Rule 7: fifteen points in a row within 1 sigma of center line

i. May signify reduced process variation (old or incorrect limits). For Xbar, can signify when variation within subgroup large compared to between subgroups

i. Rule 8: eight points in a row more than 1 sigma from center line

i. May signify a mixture of factors, erratic behavior, over control, two different processes on the same chart

II Typical errors to doing SPC

a. Not doing it

b. Not doing it in real time

i. Doing it a month after the fact for a customer report but not using it to refine your process

c. Leaving it up to the engineer or intern

i. Doing it right means proper training to shop floor and delegating the authority to stop a process if needed

d. Using lack of software or technology as an excuse

i. The most effective way is to be done by hand by the operator making the parts. Shewhart invented it this way.

e. Choosing the wrong type of chart

f. Not updating control limits after a significant process change

III Recap

a. SPC History- invented by Walter A. Shewhart working for Bell Labs in the 1920s

b. Monitors the health (pulse) of the process, and detects unanticipated change. (ekg reading?)

c. Different types of SPC charts - Most Basic I-MR, XbarR, P, U

d. Western Electric Rules - 8 Rules - Identifies low probability events. (neither good, nor bad, just different)

e. Typical errors to doing SPC, 1) Not doing it, 2) Not doing it in real time

Outro: Thanks for listening to episode 210 of the E6S-Methods podcast. Don't forget to click "like" or "dislike" for this episode in the show notes. Tap-click-done! If you have a question, comment or advice, leave a note in the comments section or contact us directly. Feel free to email me "Aaron," aaron@e6s-methods.com, or on our website, we reply to all messages. If you heard something you like, then share us with a friend or leave a review. Didn't like what you heard? Join our LinkedIn Group, and tell us why. Don't forget you can find notes and graphics for all shows and more at www.E6S-Methods.com. "Journey Through Success. If you're not climbing up, you're falling down." Leave a Review! http://bit.ly/E6S-iTunes

81 episod

Semua episod

×Selamat datang ke Player FM

Player FM mengimbas laman-laman web bagi podcast berkualiti tinggi untuk anda nikmati sekarang. Ia merupakan aplikasi podcast terbaik dan berfungsi untuk Android, iPhone, dan web. Daftar untuk melaraskan langganan merentasi peranti.